Introduction to Dosatron Fertigation

Consistent and precise nutrient delivery is essential for maximizing yield, quality, and consistency. Front Row Ag has developed a comprehensive fertigation solution built around their flexible 3-part fertilizer system, designed specifically for high-end Controlled Environment Agriculture (CEA) operations.

The foundation of Front Row Ag's system consists of Part A, Part B, and Bloom formulations. This 3-part approach offers superior customization compared to 2-part systems, allowing cultivators to fine-tune nutrient recipes for different growth stages. The system can be further enhanced with specialized additives including:

- Calcium Hypochlorite: For water sanitation and cleanliness

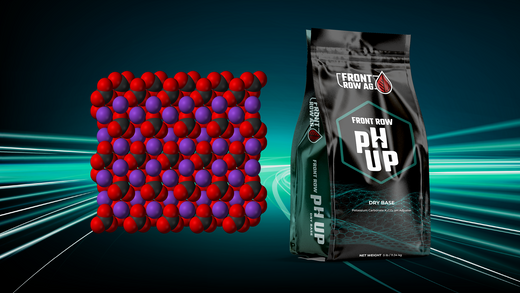

- pH Up: A calcium carbonate product designed for use with low alkalinity water

- Front Row SI: A concentrated monosilicic acid supplement

- PhosZyme: Contains mannanase and phosphatase enzymes that can be combined with Part B stock solution

- Triologic: A microbial inoculant containing plant growth promoting rhizobacteria

- BioFlo: A bio-enzymatic line cleaner for system maintenance

While Front Row Ag products are compatible with various dosing systems, Dosatron injectors have become the industry standard due to their reliability, ease of use, and cost-effectiveness. Dosatrons operate without electricity, using water pressure to inject precise amounts of concentrate into the water line. Their simple mechanical design makes them easy to service and understand, while their durability ensures long-term operation in demanding cultivation environments.

This guide will walk you through the process of configuring Dosatron panels for optimal use with Front Row Ag's product line, covering everything from basic setup principles to advanced configurations for different water sources and nutrient requirements. Whether you're setting up your first fertigation system or optimizing an existing one, you'll find the technical details needed to create the perfect configuration for your cultivation facility.

Understanding Dosatron Fertigation Technology

Dosatron injectors are water-powered, proportional injection systems that use the venturi effect to precisely mix concentrated solutions into a water line. These units require no electricity, instead using the force of flowing water to drive a piston system that draws in and mixes concentrate at a consistent ratio

How Dosatrons Work

When water flows through a Dosatron unit, it activates a piston that moves up and down, creating a vacuum that draws concentrate from a stock solution tank. The concentrate is then mixed with the water at the precise ratio set on the injector, ensuring consistent dilution regardless of water pressure or flow rate fluctuations. This mechanical precision makes Dosatrons ideal for delivering Front Row Ag's nutrient formulations.

Recommended Dosatron Models

For cultivation using Front Row Ag products, the D14 series is generally recommended. These 14-gallon-per-minute units come in two primary configurations commonly used in CEA facilities:

- D14MZ3000: Injects at 0.03% to 0.3% (1:3000 to 1:333 ratio)

- D14MZ2: Injects at 0.2% to 2% (1:500 to 1:50 ratio)

The selection between these models depends on your facility's flow requirements and the concentration of your stock solutions. Most Front Row Ag configurations will utilize multiple Dosatron units arranged in a specific sequence to deliver the complete nutrient package.

The 3-2-2 Method for Stock Solutions

Front Row Ag recommends the "3-2-2" method for preparing stock solutions for use with Dosatron systems. This standardized approach refers to the number of 25 lb. bags of each product added to individual 50-gallon stock solution drums:

- Part A: Three 25 lb. bags per 50 gal. water (1.50 lbs/gal concentration)

- Part B: Two 25 lb. bags per 50 gal. water (1.00 lbs/gal concentration)

- Bloom: Two 25 lb. bags per 50 gal. water (1.00 lbs/gal concentration)

The 3-2-2 method offers several key advantages:

- It uses whole bags, eliminating measuring errors and simplifying inventory management

- It creates equal volumes of stock concentrates that can be injected at the same rate

- It provides consistent validation parameters (EC readings) for quality control

When using additives like Phoszyme, these can be incorporated directly into the Part B stock solution (typically at 6 lbs per 50 gallons, though rates may vary based on specific cultivation needs).

Common Setup Mistakes to Avoid

The most frequent issues with Dosatron implementations for Front Row Ag systems include:

- Incorrect injection sequence: The order of injectors matters significantly, especially with pH adjusters

- Improper placement of pH adjustment injectors: pH Up should be last in sequence, while pH Down should be first

- Incompatible seals for pH solutions: Using the wrong seal material can lead to premature failure

- Missing light protection: Failing to use MC34-SHADE sleeves on mixing chambers where required

By understanding these fundamentals of Dosatron technology and proper stock solution preparation, you'll be well-positioned to implement an effective fertigation system for your CEA facility. The following sections will explore specific configurations for different water sources and cultivation requirements.

Water Source Considerations

The source and quality of your water significantly impact how you configure your Dosatron fertigation system. Front Row Ag's approach recognizes that different water sources require different pH adjustment strategies and system configurations. Let's examine the two primary water source scenarios: Reverse Osmosis (R.O.) water and City/Well water.

Low-Alkalinity Water: RO or Rainwater Systems (Using pH Up)

Reverse Osmosis systems produce water with low alkalinity, low electrical conductivity (EC), and minimal mineral content. While this creates a "blank slate" for minerals, it also presents unique challenges:

- Low buffering capacity: R.O. water lacks alkalinity, making it highly sensitive to pH fluctuations when fertilizers are added

- Natural pH depression: When fertilizers are added to R.O. water, the pH typically drops, requiring upward adjustment

- Configuration needs: R.O. water setups require pH Up injection as the final step in the fertigation sequence

For R.O. water systems, Front Row Ag recommends:

- Starting with calcium hypochlorite injection for water sanitation (when applicable)

- Adding calcium hypochlorite and silica supplements at the beginning of the injection sequence

- Following with the three-part nutrient injection (FRA Part A, Part B, and Bloom)

- Finishing with pH Up as the last injector in the sequence

For pH Up solutions, Front Row Ag offers products based on:

- Potassium carbonate: A milder base that provides gradual pH changes and adds buffering capacity to stabilize solution pH. While adjustments may take up to 15 minutes to fully take effect, this option provides more stable results and can be directly added to reservoirs or diluted for injection.

City/Well Water Systems (Using pH Down)

City water and well water typically contain more minerals, resulting in higher EC readings and natural alkalinity. These characteristics create different requirements:

- High buffering capacity: These water sources contain carbonates that resist pH changes

- Natural pH elevation: The alkalinity in these water sources often requires downward pH adjustment

- Configuration needs: City/well water setups require pH Down injection as the first step in the fertigation sequence

For city/well water systems, Front Row Ag recommends:

- Starting with calcium hypochlorite for water sanitation (when applicable)

- Following with pH Down

- Adding Front Row SI (when applicable)

- Completing with the three-part nutrient injection (FRA Part A, Part B, and Bloom)

For pH Down solutions, common options include:

- Phosphoric acid: The most frequently used pH Down product in hydroponics, providing strong and immediate pH effects

- Sulfuric acid: Another effective option that doesn't add NPK ions that might affect fertilizer ratios (requires careful handling due to its caustic nature)

Water Pre-Treatment Recommendations

Before water enters your Dosatron system, Front Row Ag recommends appropriate pre-treatment:

- Filtration through carbon filters to remove chlorine and chloramines (for city water)

- R.O. filtration for high-TDS water sources or when precise control is required

- Appropriate pre-filtration to prevent particulate matter from entering the Dosatron system

- Potentially calcium hypochlorite addition to maintain low microbial accounts in the water storage tanks.

Regardless of water source, the first Dosatron injector in your system should typically be reserved for calcium hypochlorite water sanitation unless it’s already being injected prior to the water storage tank.

Panel Configuration Options

Dosatron panels for Front Row Ag fertigation systems consist of several key components that work together to ensure precise and reliable nutrient delivery. Understanding these components and their functions is essential for proper system setup and maintenance.

Standard Components

A typical Front Row Ag Dosatron panel includes the following standard components:

- HYKSTART-STD: This starter kit provides the foundation of the system, including a filter, pressure gauge, and bypass valve. These components ensure clean water flow, proper pressure monitoring, and the ability to bypass the system if needed.

-

D14MZ: These are the Dosatron injector units themselves. The D14MZ2 model injects at 0.2% to 2% (1:500 to 1:50 ratio), while the D14MZ3000 (where applicable) injects at 0.03% to 0.3% (1:3000 to 1:333 ratio). The letters in the model numbers indicate specific configurations:

- VF: Equipped with Viton seals for use with acidic solutions (pH Down)

- AF: Equipped with Aflas seals for use with basic solutions (pH Up)

- The D14MZ2AFBPHY model is specifically noted as a special-order item for pH Up applications

- HYKMC34: This is the mixing chamber where the injected concentrate mixes with the water stream

- MC34-SHADE: This light protection sleeve covers the mixing chamber to protect light-sensitive nutrients and prevent algae growth

- WHA34-SS-KIT: This is a water hammer arrestor kit that protects the system from pressure spikes that might occur when valves close quickly elsewhere in the irrigation system

Optional Components

- HYKMON: This monitoring kit includes pH and EC sensors. While listed as optional, Front Row Ag recommends monitoring solution parameters at the batch tank and at the dripper rather than at the panel exit. This is because chemical reactions (particularly pH adjustments) may still be occurring as the solution exits the panel, potentially resulting in misleading readings.

Recommended Dosatron Panel Configurations for Front Row Ag Fertilizer by Water Source (City Water or R.O. Water) With Parts List

Get the printable PDF of this information here

Configuration Best Practices

When setting up your Dosatron panel, consider these important factors not immediately visible in the diagrams:

- Inlet pressure: Ensure your water supply provides sufficient pressure at your required flow rates. Inadequate or excessive pressure can result in inconsistent injection rates.

- Mounting height: Mount the panel at a comfortable working height that allows easy access to adjustment dials and maintenance points.

- Service access: Leave adequate space around the panel for maintenance activities like changing seals or adjusting injection rates.

- Stock solution placement: Position stock solution tanks close to the panel but with enough clearance to prevent contamination during filling operations.

- Flow direction: Always confirm that water flows through the system in the correct direction as indicated by arrows on the components.

-

Water Pressure Considerations:

- Official operating range: 4.3 to 85 PSI (0.3 to 6 bar)

- Optimal performance: While Dosatrons will function across this range, Front Row Ag has observed that the systems tend to work best at the higher end of the pressure spectrum

- Pressure regulation: If your water supply pressure exceeds 85 PSI, a pressure regulator should be installed upstream of the Dosatron panel

By selecting the appropriate components for your water source and correctly configuring your Dosatron panel, you can create an efficient fertigation system that delivers precise nutrient formulations for optimal plant growth.

Injection Sequence Principles

The order in which nutrients and additives are injected into your water system is critical for effective fertigation. Front Row Ag has developed specific injection sequences based on water chemistry principles that ensure optimal nutrient availability while preventing adverse chemical interactions.

The Science Behind Injection Sequence

The recommended injection sequences aren't arbitrary—they're designed based on several key chemical principles:

-

Optimizing Solubility:

- Part A contributes the most weight and electrical conductivity (EC) to the solution, so it's positioned strategically in the sequence

- As the sequence progresses through Part B and Bloom, the EC and weight contributions gradually decrease while acidity increases, helping maintain solubility as new components are added

-

pH Management:

- More acidic components are added in a specific order to aid in solubility

- The "pH Down first, pH Up last" principle maintains optimal solubility throughout the process

- Most minerals have higher solubility at lower pH, which is why pH Up is recommended as the final step when increases are required

-

Preventing Precipitation:

- The sequence prevents unwanted chemical reactions between incompatible components

- Non-organic additives that might form precipitates are added early in the process when water EC is lowest

pH Up Configurations (low-alkalinity water)

When using very low-alkalinity water that requires pH adjustment upward:

-

pH Up must be the last injector in the sequence

- This ensures all nutrients are fully dissolved before pH is raised

- Using pH Up earlier could cause precipitation of certain nutrients

-

CalHypo and Si placement:

- If calcium hypochlorite (for sanitation) and silica supplements are used, they should be added at the beginning of the injection sequence

- This positioning allows maximum contact time and ensures they don't interfere with the main nutrient components

The complete sequence for R.O. water systems should be:

- Calcium Hypochlorite (if used)

- Front Row Si (if used)

- FRA Part A

- FRA Part B (with PhosZyme if applicable)

- FRA Bloom

- pH Up (final position)

pH Down Configurations (City/Well Water)

When using city or well water that requires pH adjustment downward:

- CalHypo first, if applicable

-

pH Down should be the next injector in the sequence

- This counters alkalinity early, preventing interference with nutrient solubility

- It creates optimal conditions for the nutrients that follow

-

Si placement, if applicable

- Silica should be positioned after pH Down but before the three-part nutrient system

The complete sequence for city/well water systems should be:

- Calcium Hypochlorite (if used)

- pH Down

- Front Row Si (if used)

- FRA Part A

- FRA Part B (with PhosZyme if applicable)

- FRA Bloom

Exceptions and Special Considerations

While the standard sequences work for most operations, there are situations that may require modifications:

- Higher Flow Requirements: Facilities with higher water flow rates may need to use D40 series Dosatron injectors instead of the standard D14 series

- Additional Additives: When incorporating products beyond the standard Front Row Ag line, consult with Front Row Ag technical support for optimal placement in the injection sequence

- Custom Recipes: Custom nutrient recipes may require adjustments to the standard injection sequence to prevent unwanted chemical interactions

By following these injection sequence principles, you can ensure your Front Row Ag fertigation system delivers nutrients in the most effective and efficient manner possible.

Seal Options for pH Adjustment

One of the most critical aspects of Dosatron setup is using the appropriate seal material for different pH adjustment solutions:

- Aflas (AF) seals: These seals are specifically designed for use with basic (high pH) solutions such as potassium carbonate used in pH Up applications. The D14MZxx-AFBPHY model featuring Aflas seals is the correct choice for pH Up injection.

- Viton (VF) seals: These seals are designed for use with acidic (low pH) solutions such as phosphoric or sulfuric acid used in pH Down applications. The D14MZxx-VFBPHY models featuring Viton seals should be used for pH Down injection.

Using the wrong seal material with your pH adjustment solution will lead to premature seal failure, leaks, and inconsistent injection rates. The AFBPHY (with Aflas seals) is noted as a special-order item, so plan accordingly when configuring a system that requires pH Up.

Physical Installation Best Practices

When installing your Dosatron panel, consider these guidelines:

- Mounting height: Install the panel at a height that allows comfortable access to adjustment dials, typically around eye level for the average operator

- Flow direction: Ensure water flows through the system in the direction indicated by arrows on the components

- Horizontal mounting: Dosatron injectors should be mounted vertically, but the overall panel should be level horizontally

- Bypass valve: Configure the bypass valve (included in the HYKSTART-STD kit) to allow system maintenance without disrupting water flow to your facility

- Stock solution tanks: Position these below the injectors to prevent siphoning, preferably on spill containment pallets

- Filter access: Ensure easy access to the filter for regular cleaning and maintenance

Initial Setup and Calibration

Once your Dosatron panel is physically installed:

- Flush the system: Run clean water through the system before connecting stock solutions to remove any debris from installation

- Prepare stock solutions: Mix Front Row Ag products according to the 3-2-2 method described earlier

- Set injection rates: Adjust each Dosatron to the appropriate injection rate based on your crop requirements and stock solution concentration

- Verify operation: Ensure each injector draws solution correctly by checking the visual indicators on each unit and validating injection volumes as necessary

- Calibrate: Use EC and pH meters to verify that the final solution matches your desired specifications

By following these setup guidelines, you'll create a reliable and effective fertigation system that delivers precise nutrient formulations to your crops.

Monitoring Best Practices

Proper monitoring of your fertigation solution is critical for consistent results and plant health. Front Row Ag recommends specific monitoring practices that differ from conventional approaches to ensure accurate measurements and optimal performance.

Strategic Monitoring Points

While it might seem intuitive to monitor the solution as it exits the Dosatron panel, Front Row Ag recommends a different approach:

-

Primary monitoring points:

- The batch tank (if applicable)

- At the dripper/emitter where the solution reaches the plants

-

Why avoid panel exit monitoring:

- Incomplete chemical reactions: Some pH adjusters, particularly buffering agents like potassium carbonate, require up to 15 minutes to fully stabilize. Measuring too close to the injection point can result in misleading pH readings.

- Sanitizer effectiveness: For systems using calcium hypochlorite for water sanitation, what matters most is the sanitizing power at the plant site. Due to residual demand throughout the system, much of the free chlorine may be consumed before reaching the plants. Monitoring only at the panel exit can give a false sense of sanitizing capacity.

- Homogenization time: Complete mixing of all injected components requires time and distance from the injection points. Early measurements may not represent the true composition of the solution that will reach your crops.

Recommended Parameters for Front Row Ag Products

While specific targets may vary based on crop stage and variety (detailed feed charts are available in separate Front Row Ag resources), general targets include:

- pH: Approximately 5.8 for most applications

- EC: Generally between 2.5 and 3.0 mS/cm

- Water temperature: 65-72°F for optimal nutrient uptake

Essential Monitoring Tools

Beyond standard pH and EC meters, Front Row Ag recommends:

- Chlorine test strips: For systems using calcium hypochlorite, these provide a quick way to verify sanitizing power at the plant site

- ORP (Oxidation-Reduction Potential) meter: A more precise tool for measuring water sanitation effectiveness, particularly valuable for larger operations where consistent sanitation is critical

- Temperature monitoring: Water temperature affects both nutrient solubility and uptake, making it an important parameter to track

Calibration and Maintenance

For accurate monitoring:

- Calibrate pH and EC meters regularly (at least weekly for commercial operations)

- Clean probes according to manufacturer recommendations

- Replace test solutions and calibration fluids at recommended intervals

- Keep records of readings to track trends and identify issues early

By implementing these monitoring best practices, you'll gain more accurate insights into your fertigation system's performance and ensure your plants receive the precise nutrient profile they need for optimal growth and production.

Fertigation Maintenance and Troubleshooting

Proper maintenance is essential for ensuring the long-term reliability and performance of your Dosatron fertigation system. While this article focuses primarily on configuration, it's important to follow established maintenance protocols to keep your system operating at peak efficiency.

To validate injection volumes, use this process:

Injector Volume Validation Instructions

Dosatron Maintenance Resources

For comprehensive maintenance procedures, schedules, and troubleshooting guidance, Front Row Ag recommends consulting the official Dosatron Best Practices Guide. This resource provides detailed information on:

- Regular maintenance tasks and schedules

- Seal replacement procedures

- Troubleshooting common issues

- Preventative maintenance recommendations

- Cleaning and sanitization protocols

Key Points

Key takeaways from this guide include:

- Water source matters: Different water sources require different pH adjustment approaches and injection sequences. Understanding whether you need pH Up (for R.O. water) or pH Down (for city/well water) configuration is the first critical decision in your system design.

- Component selection is critical: Using the right Dosatron models with appropriate seals (Aflas for basic solutions, Viton for acidic solutions) ensures reliable operation and prevents premature component failure.

- Injection sequence follows chemical principles: The recommended sequences aren't arbitrary—they're designed to optimize solubility, prevent precipitation, and ensure nutrients are available to your plants in the most effective form.

- Monitoring strategy affects accuracy: By monitoring at the batch tank and at the dripper rather than at the panel exit, you'll get more accurate readings that reflect what your plants actually receive.

- The 3-2-2 method simplifies stock solution preparation: This standardized approach to mixing Front Row Ag's three-part system ensures consistency while eliminating measuring errors.

For additional support or custom configuration advice for your specific facility, don't hesitate to reach out to Front Row Ag's technical support team.